WOLF CREEK WHIPS

Durable Handmade Quality

Background

I’m Rachel McCollough of Wolf Creek Whips. I have been building whips by hand completely for several years now. I learned much of what I know by studying others’ work and gaining a HUGE amount of learning from their teaching at Whip Basics The Forum, a community started and operated by a dear friend of mine, Robert Amper. I have had the great opportunity to have whips reviewed by Robby professionally. Robby is the producer of the Whip Basics dvd series. I have been blessed to gain close friendship and detailed learning from some of the finest whipmakers in the world. Giovanni Celeste, Simon Martin, Mark Elloitt, Roy Partin, Tyler Blake, Matt Galizia, Jessie Edwards, Ben Varsek, Jyri Havari, Jeff Roseborough, Glen Denholm. There are several friends I have not mentioned that also make whips and some who do not that have been integral to both my learning and quality of life since. Bernie Wojcicki also has had a very strong influence on my work, as has the research on the Florida Cracker Cow Whip. I have learned a lot from repairing local cow whips. I am primarily a cow whip maker, and my whole whipmaking style is based majorly on the classical type of Florida Cracker Cow Whip.

I started Emergency Medical Technician school in 2017. I was around 36 years old and had never sat in a classroom as I am homeschooled. I progressed to Paramedic in 2018, graduating and gaining my NRP in September of 2019. I have continued working as a Paramedic and now a Registered Nurse.

Nothing I have done could be accomplished without each person who has contributed to my life as family and friends do, even when they don’t even know they have impacted another in a significant way. My husband Lonnie has been a farrier, farmer, dog trainer, and firefighter. He has been a constant support for over 22 years. Our two grown sons, Garret and Hagen, have always assisted with dishes, laundry and other chores as well as helping in any endeavor we have undertaken.

My philosophy when building a whip is simple:

-A whip should be built where it moves like a living thing, like a snake.

-It should have a backbone, without a break in each connection.

-It should always taper continuously from the heel to the tip of the cracker.

-It should be a solid and soundly built tool to last as long as possible.

-A well built whip, carefully designed, is a thing of true beauty.

-A Craftsman can be an Artisan, but an Artisan is not always a Craftsman. A Master Whipmaker is both Craftsman and Artisan.

I’ve been out of pocket for quite a while. I have one more year of school as a nurse left. My building time will be limited for the foreseeable future, so I will be building whips on a one-of basis. When a whip is complete I will place it in my shop. Thank you for your interest in Wolf Creek Whips.

Build Process

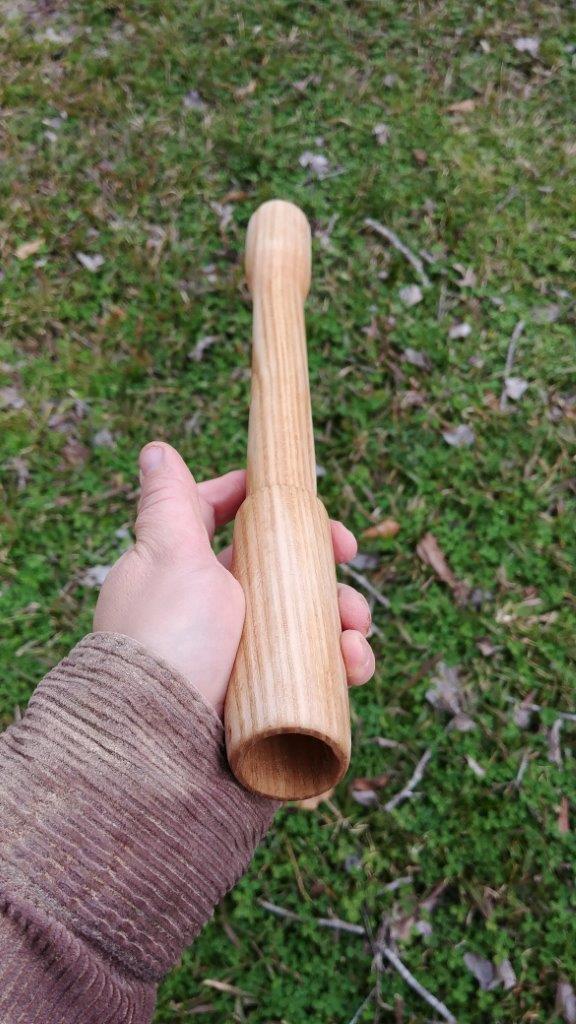

Each handle is painstakingly hand shaped from exotic wood or a more local hand-picked hard wood such as ash or hickory. After shaping by hand with a rasp, the handle is hand sanded and finished with a few coats of Tung Oil.

Each whip is made from nylon coreless paracord (with exception of kangaroo whips) that begins with a Twisted Taper Core, bellies plaited and connected with each prior layer, and the overlay either a simple solid color or specifically designed plaiting for that whip. The whip is then waxed in a mixture of paraffin and beeswax.

This detailed process completely by hand produces a nose heavy whip that rolls out fluidly with little to no effort by the whipcracker. Dyneema crackers included make for a long lasting, solid tool.

Rounding the Blank

The chosen blank is rounded by hand with a horse hoof rasp.

Centering and Balance

The blank is marked for center and balance, and the ends are rounded. Sanding will take place after drilling the hole for the whip thong.

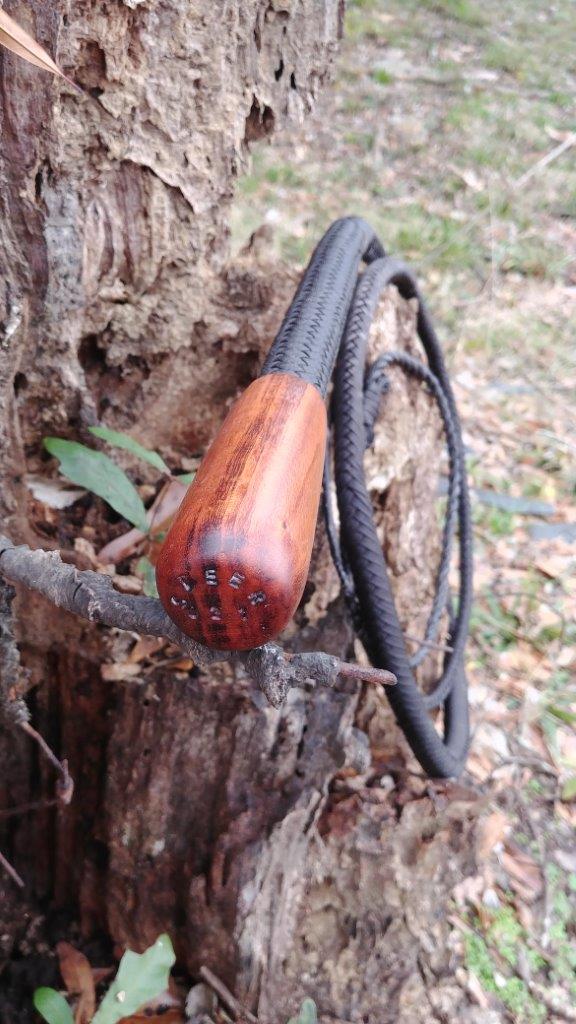

Finished Handle

Tung oil is applied in a few layers. The finished handle will be left as is or a brand will be wood burned by hand onto the handle.